X400 vs Funmat HT Printer Comparison

The Funmat HT Enhanced was groundbreaking for its time. However, its feature set has fallen behind the competition as of late.

Automatic bed leveling is limited to 3 touch points on the plane, with a highly finicky and unreliable mechanical switch. The 3D Labs X400 with its BL Touch hall sensor is far more accurate with 256-point mesh leveling.

Utilizing dual materials, breakaway high-temperature support material, or even soluble supports is impossible on the Funmat HT's single extruder without paying for an external device.

The Funmat HT's firmware is based on open-source Marlin, yet the company refuses to release the source code per the GPL license. For this reason, the Funmat will have difficulty being used in any DoD or aerospace applications that require any kind of serious certifications.

The bed in the Funmat HT is roughly 1/8" thick, hardly enough to prevent sagging edges at high temperatures resulting in difficult headaches trying to perfect your first layer. The X400's patent-pending cast tooling plate .25" thick bed is as flat as they come, even at extreme temperatures exceeding 215C.

The Chinese-made Funmat can't compare to the X400's value add for your business.

Note: All images, logos, trademarks and any other information on this page are the property of their respective owners and are used solely for identification purposes on this page.All information is provided based on publicly published or available information from respective vendors' website or publications, and their accuracy is not guaranteed. 3D Laboratories LLC is in no way affiliated with any 3rd party brand, trademark, product or any other entity presented here for identification purposes.

Specifications |

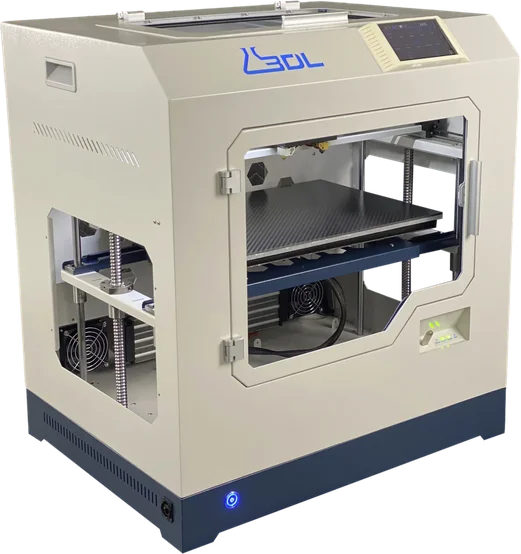

3D Labs X400 |

Intamsys Funmat HT |

| Maximum Build Volume | 350mm x 300mm x 300mm | 260 x 260 x 260 mm |

| Max print speed | 250mm/s | 300mm/s (Claimed, but highly unlikely to be stable) |

| Minimum Layer Height | 40 microns | 50 microns |

| Connectivity Options | USB, Ethernet (ITAR ready) | USB (Non-itar compliant) |

| Max Nozzle Temp | 500C | 350C |

| Max Bed Temp | 220C | 160C |

| Max Chamber Temp | 95C | 90C |

| Compatible Materials | CF-PEKK-C, CF-PEEK, CF-PEI, PEEK, PEKK-A, PEKK-C, PSU, PPSU, PP, PEI9085, Nylons (PA/all), PC, ABS, ASA, PETG, PCTG, PLA, HT-PLA, BASF Metal | PEEK, PEI, PPSU, PA/CF, PC, PC Alloys, PA, ABS,, Nylon, ASA, PETG, ESD-Safe, HIPS, TPU, PLA, PVA |

| Availabe Nozzle Sizes | 0.2, 0.4, 0.6, 0.8, 1.0, 1.2 mm | 0.1, 0.25, 0.4, 0.6, 0.8 mm |

| Dual Extrusion | ||

| Certified Material Profiles | ||

| Manual Bed Leveling | ||

| Assisted Manual Bed Leveling | ||

| Auto Bed Leveling | ||

| Internal Filament Storage | ||

| Touch Screen | ||

| Touch Screen Size | 5" | 3.5" |

| Enclosed Chamber | ||

| Actively Heated Chamber | ||

| Filament Runout Detection | ||

| ITAR Compliant | ||

| AS9100D Ready | ||

| Assembled in USA | ||

| Data at Rest File Encryption | ||

| Role Based Access Controls | ||

| Private Network Print Farm Clustering | ||

| Military Grade SSL Encryption | ||

| 64-Bit Controller | ||

| NAFTA Sourced Electrical Components | ||

| Onboard Computer | ||

| Thermal Runaway Protection | ||

| Thermal Bed Fuse | ||

| HEPA Filtration System | ||

| Commercial Slicing Software | ||

| 3rd Party Slicer Compatible | ||

| Touch Screen User Interface | ||

| Web Interface | ||

| Gcode Picture Preview | ||

| Gcode Editing | ||

| Gcode Area Avoidance | ||

| Onboard Multi-User Project Management |