X400 vs Tractus3D T850P Printer Comparison

The Tractus3D T850P is a high-temperature Delta-based printer. While the speed capabilities of a Delta are impressive, printing high-temperature materials such as PEEK and ULTEM is not viable at these speeds. PEEK and Ultem require slower printing for maximum layer bonding, or you could risk producing a sub-optimal part.

With a low chamber temperature of 80C, maintaining an adequate ambient temperature required for high-temperature materials beyond 80-100mm could prove very challenging. The 3D Labs X400 chamber at 95C will allow for additional capabilities with these materials at the price point.

The Tractus offers a respectable bed temperature of 175C. However, the X400's 220C bed still dwarfs the competition. The additional bed heat achieved on the X400 will allow the printing of more extensive, flatter parts with minimal warping.

The 3D Labs X400 delivers a more cost-effective value added solution for your business.

Note: All images, logos, trademarks and any other information on this page are the property of their respective owners and are used solely for identification purposes on this page.All information is provided based on publicly published or available information from respective vendors' website or publications, and their accuracy is not guaranteed. 3D Laboratories LLC is in no way affiliated with any 3rd party brand, trademark, product or any other entity presented here for identification purposes.

Specifications |

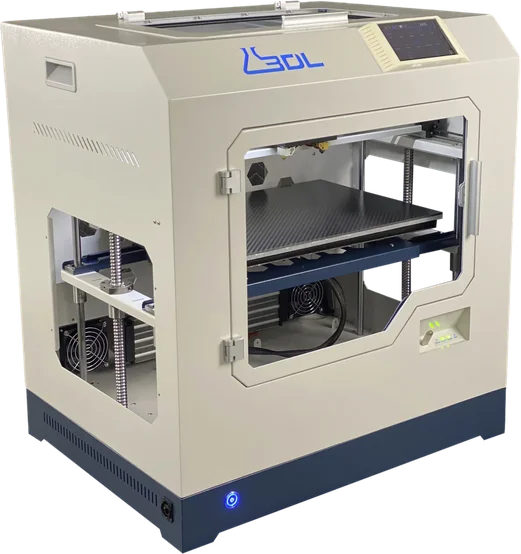

3D Labs X400 |

Tractus3D T850P |

| Maximum Build Volume | 350mm x 300mm x 300mm | 280 mm diameter |

| Max print speed | 250mm/s | 450 mm/s (Not actually possible with PEEK/Ultem because of dwell times) |

| Minimum Layer Height | 40 microns | 10 microns (Hardly viable with FDM) |

| Connectivity Options | USB, Ethernet (ITAR ready) | LAN (ITAR ready), USB |

| Max Nozzle Temp | 500C | 450C |

| Max Bed Temp | 220C | 175C |

| Max Chamber Temp | 95C | 80C |

| Compatible Materials | CF-PEKK-C, CF-PEEK, CF-PEI, PEEK, PEKK-A, PEKK-C, PSU, PPSU, PP, PEI9085, Nylons (PA/all), PC, ABS, ASA, PETG, PCTG, PLA, HT-PLA, BASF Metal | PEEK, PEI, PLA, PRO1, PET-G, ABS, ASA, Facilan C8, TPU/TPE, Nylon, PC, Fillers |

| Availabe Nozzle Sizes | 0.2, 0.4, 0.6, 0.8, 1.0, 1.2 mm | 0.1, 0.25, 0.4, 0.6, 0.8, 1.0 mm |

| Dual Extrusion | ||

| Certified Material Profiles | ||

| Manual Bed Leveling | ||

| Assisted Manual Bed Leveling | ||

| Auto Bed Leveling | ||

| Internal Filament Storage | ||

| Touch Screen | ||

| Touch Screen Size | 5" | 7" |

| Enclosed Chamber | ||

| Actively Heated Chamber | ||

| Filament Runout Detection | ||

| ITAR Compliant | ||

| AS9100D Ready | ||

| Assembled in USA | ||

| Data at Rest File Encryption | ||

| Role Based Access Controls | ||

| Private Network Print Farm Clustering | ||

| Military Grade SSL Encryption | ||

| 64-Bit Controller | ||

| NAFTA Sourced Electrical Components | ||

| Onboard Computer | ||

| Thermal Runaway Protection | ||

| Thermal Bed Fuse | ||

| HEPA Filtration System | ||

| Commercial Slicing Software | ||

| 3rd Party Slicer Compatible | ||

| Touch Screen User Interface | ||

| Web Interface | ||

| Gcode Picture Preview | ||

| Gcode Editing | ||

| Gcode Area Avoidance | ||

| Onboard Multi-User Project Management |