Metal replacement with high-temperature polymers

Is metal replacement viable with 3D printed polymers? The answer is yes, and we'll explain why in this article.

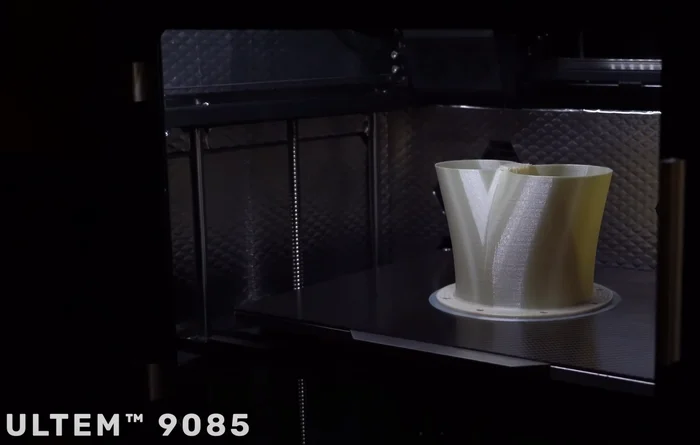

The use of high-temperature 3D printed polymers, such as PEEK and PEI 9085, to replace metal parts in various industries has been gaining traction in recent years. These advanced polymers offer a number of advantages over traditional metal parts, including improved performance and cost savings. The 3D Labs HTX 3D printer is an excellent option for cost-effectively printing these materials and replacing small to mid-sized metal parts.

Another important aspect to consider is the fact that high-temperature 3D printed polymers are already being used to replace metal parts in various industries. The aerospace industry, for example, has been a pioneer in the use of these advanced materials. Companies like Boeing have been using 3D printed polymers such as PEEK in the production of aircraft parts for several years, replacing metal parts in areas such as engine components, interior cabin elements, and even in structural components. These parts have been proven to be not only cost-effective but also to offer improved performance and weight savings. The adoption of these materials in aerospace industry is a clear indication of their reliability and the potential they hold for other industries as well.

One of the key advantages of using high-temperature 3D printed polymers is their ability to withstand high temperatures. PEEK, for example, has a maximum continuous use temperature of up to 500°F (260C), making it an ideal choice for applications in high-temperature environments such as aerospace and automotive. PEI 9085, on the other hand, has a maximum continuous use temperature of up to 338°F (170C), making it suitable for use in a wide range of industrial applications.

Another advantage of high-temperature 3D printed polymers is their high strength and stiffness. PEEK, for instance, has a tensile strength of up to 110 MPa and a Young's modulus of up to 3.6 GPa. This makes it an excellent choice for use in applications that require high strength and stiffness, such as gears, bearings, and other mechanical parts. PEI 9085 also has high strength and stiffness, with a tensile strength of up to 67 MPa and a Young's modulus of up to 2.63 GPa.

In addition to their high-temperature and mechanical properties, high-temperature 3D printed polymers also offer cost savings over metal parts. Metal parts often require expensive tooling and machining, as well as additional coatings and treatments to improve their performance. 3D printing, on the other hand, allows for the production of complex geometries and internal structures without the need for expensive tooling. The 3D Labs HTX 3D printer, in particular, is a cost-effective option for printing these advanced polymers and replacing small to mid-sized metal parts.

High-temperature 3D printed polymers are also highly customizable, allowing for the creation of unique and complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods. This opens up new opportunities for innovation in various industries.

It also allows for the creation of parts with improved performance characteristics, such as increased strength or reduced weight, which can lead to greater efficiency and cost savings.

High-temperature 3D printed polymers are also corrosion-resistant and are able to withstand harsh chemical environments. This makes them an ideal choice for use in industries such as chemical processing and oil and gas, where traditional metal parts may not be suitable.

Despite the advantages of high-temperature 3D printed polymers, there are some limitations to be aware of. One limitation is that these polymers are not suitable for use in applications that require high levels of electrical conductivity. Additionally, 3D printing with high-temperature polymers can be more expensive than traditional manufacturing methods, due to the need for specialized equipment and expertise.

In conclusion, the use of high-temperature 3D printed polymers, such as PEEK and PEI 9085, is becoming increasingly popular as a replacement for metal parts in various industries. The 3D Labs HTX 3D printer is an excellent option for cost-effectively printing these materials and replacing small to mid-sized metal parts. These advanced polymers offer a number of advantages over traditional metal parts, including improved performance, cost savings, and customization opportunities. However, it's important to consider the limitations and to consult with experts for guidance in selecting the right material for the application.

Add a Comment